Join KIN-TEK at Pittcon 2026 Booth #3130!

KIN-TEK will be featuring the FlexMixer™ – Multi-Gas Blending/Diluting System and the new Span Chek™ 2400 Portable Calibration System.

The FlexMixer™ Multi-Gas Blending/Diluting System mixes or dilutes up to 10 separate gas feeds (or cylinder sources) to one Span Gas output. Controlled by user friendly software installed on the user PC, the FlexMixer™ is an economical and functional solution for a broad range of applications. click for more

The Span Chek™ 2400 is your grab-and-go portable solution for creating accurate, NIST traceable gas standards for calibrating ambient air monitors, detectors, and fence-line systems. It delivers repeatable multi-point concentrations directly at the sensor using up to four Trace Source™ disposable permeation tubes. click for more

Reliable solutions for Analyzers, Detectors, and Sensors

KIN-TEK Analytical, Inc. utilizes Trace Source™ permeation tubes to offer complete solutions for creating custom gases for over 550 gas compounds. Get the accuracy you need with multi-point gas calibration—tailored to your application.

- Trace Source™ Permeation Tubes – Disposable and refillable permeation tubes – for over 550 chemicals.

- Span Pac™ I – Industrial, process GC applications in hazardous atmospheres.

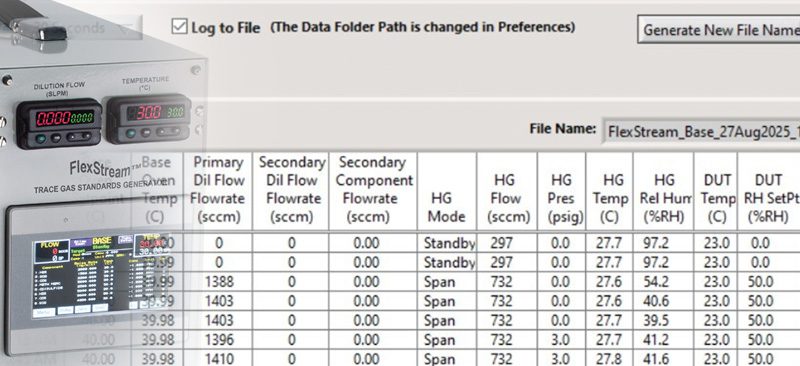

- FlexStream™ – Lab, QA/QC, and research development.

Read More! Use KIN-TEK’s Span Chek™ 2400 Portable Calibration System for portable calibration! “Simplifying Gas Monitor Performance Verification Protocols using a Portable Permeation System” by Danet Vrazel

Danet M. Vrazel worked in the Chemical Industry with companies such as Hoechst Celanese and Solutia and did research in the Chemical Pathology Department at UTMB Galveston before working with KIN-TEK in 2001. As a Technical Sales/Service Representative for KIN-TEK, Ms. Vrazel learned techniques for calibrating gas analytical devices using permeation tubes and gas standard generators. Ms. Vrazel has been with KIN-TEK for over 20 years providing gas calibration solutions to the gas analyzer industry and working with customers all over the world. Now as Vice President, Ms. Vrazel uses her business experience and technical expertise to guide business operations.

Danet M. Vrazel worked in the Chemical Industry with companies such as Hoechst Celanese and Solutia and did research in the Chemical Pathology Department at UTMB Galveston before working with KIN-TEK in 2001. As a Technical Sales/Service Representative for KIN-TEK, Ms. Vrazel learned techniques for calibrating gas analytical devices using permeation tubes and gas standard generators. Ms. Vrazel has been with KIN-TEK for over 20 years providing gas calibration solutions to the gas analyzer industry and working with customers all over the world. Now as Vice President, Ms. Vrazel uses her business experience and technical expertise to guide business operations. The Span Chek

The Span Chek