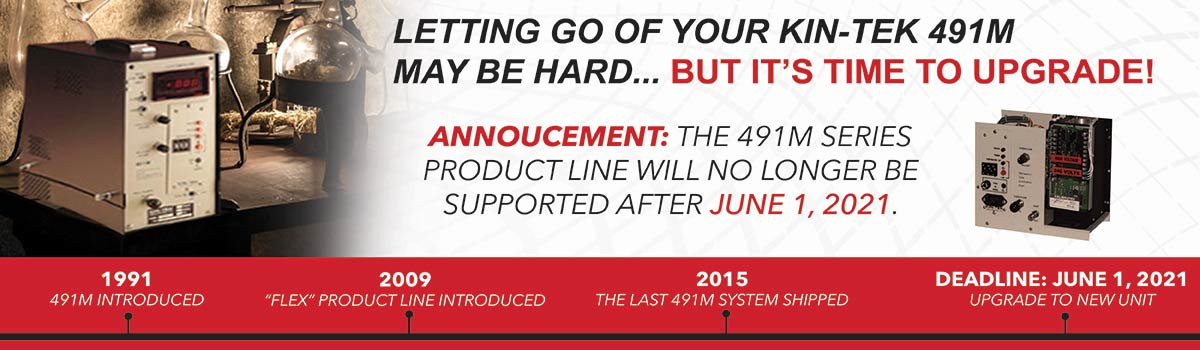

It may seem like your 491M will last forever, but it is time to UPGRADE your system to a new Gas Standard Generator.

Beginning June 1, 2021, KIN-TEK Analytical, Inc. will no longer be able to support the older 491M Series.

KIN-TEK has been offering discounts toward a trade-up to a newer model standard generator with verification of ownership of older models. We apologize for any inconvenience this may cause but are willing to work with you through this transition. For more information see below or click to request a quote for Trade-Up.

Let’s take a walk through the years…

1991: The 491M Gas Standard Generator was introduced by KIN-TEK Laboratories, Inc. The 491M was a manually operated permeation system that created trace calibration gas from permeation tubes for calibrating gas analytical equipment. It took permeation tube technology through the 1990s and into the new millennium with almost 25 years of sales and operation. Its versatility and expandability to use different modules to create a custom calibration gas mixture made the 491M unique and robust.

2009: Industry updated components and technology changes created a challenge for sustainability for the 491M Product line. KIN-TEK responded by developing new products that continued the reign of flexibility and expandability that the 491M offered. In 2009, KIN-TEK developed the first release of its “Flex” product line. The rise of the automated FlexStream™ Gas Standard Generator picked up where the 491M left off and soon many parts became expensive to replace in the manually operated 491M.

2015: The last 491M system was shipped in 2015 and shortly after a decision was made to discontinue the instrument product line due to limited parts, increased repair costs, and the demand for increased technology. KIN-TEK continued supporting the 491M through Recertification Services but informed customers of the limited part availability if a repair was required.

2021: Sadly, the time has come for KIN-TEK to discontinue the support of the legacy models and 491M Product line it is has offered for over 30 years. Though we know some customers will be as heart broken as we are to let this model go, we are not leaving you without replacements. For over a year now, KIN-TEK Analytical has been offering customers trade-in/trade-up discounts on new instruments if they retire their 491M, older Span Pac 61, or CO395 instrument known to all share the same older parts and components. Call or click to request a quote to find out more about what discount you can receive to upgrade to a newer, even more robust, advanced, “Flex” product.

Starting June 1st, 2021 KIN-TEK will no longer be able to support the older 491M (or other models) for services. Prepare now before it is too late!

Click For More … Gas Standard Generators

Click For More … Trace Source™ Permeation Tubes