The Importance of Data Acquisition in Gas Analyzer Calibration…

Acquiring data to verify the performance of an instrument is vital for traceability and analysis of trends for accuracy, reliability and compliance. Most gas analytical devices have integrated software to capture analytical data for comparison to a saved calibration. However, there are limitations in the ability to directly compare analyzer response data and gas standard values during calibration if a cylinder gas standard is used. Calibration information provided for the cylinder is static and relative to when the cylinder was analyzed not when it is used during calibration so differences may exist that affect overall calibration performance without the user’s knowledge. Actively recording calibration gas data as it is generated creates unique advantages over traditional cylinder gas calibration and is done using a permeation system.

Read more about data acquisition in gas analyzer calibration …

Quick Links!

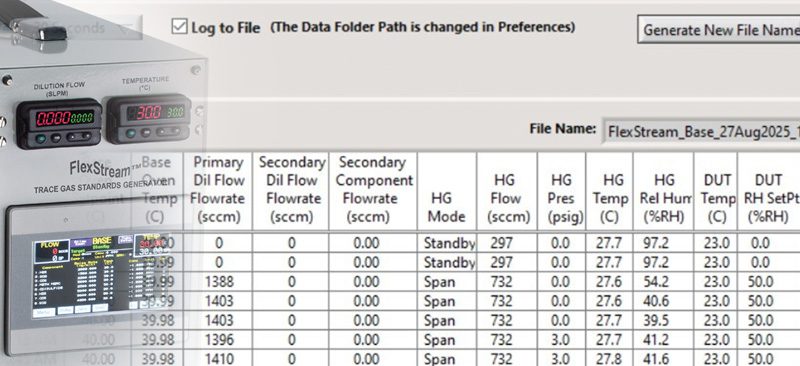

KIN-TEK FlexLinkTM Software KIN-TEK supplies a Windows® executable program named “FlexLink™” to setup, monitor and control the generation of multi-component concentrations with KIN-TEK’s FlexStream™ gas standards generator.

KIN-TEK FlexLinkTM Software KIN-TEK supplies a Windows® executable program named “FlexLink™” to setup, monitor and control the generation of multi-component concentrations with KIN-TEK’s FlexStream™ gas standards generator.

KIN-TEK FlexStream Gas Standard Generator The KIN-TEK Analytical FlexStream™ System is ideally suited for creating trace concentration – ppm, ppb, and pptr – mixtures. The FlexStream™ uses KIN-TEK Trace Source™ disposable, refillable and diffusion permeation tubes for over 550 Supported Chemicals.

More about the author:

Danet M. Vrazel worked in the Chemical Industry with companies such as Hoechst Celanese and Solutia and did research in the Chemical Pathology Department at UTMB Galveston before working with KIN-TEK in 2001. As a Technical Sales/Service Representative for KIN-TEK, Ms. Vrazel learned techniques for calibrating gas analytical devices using permeation tubes and gas standard generators. Ms. Vrazel has been with KIN-TEK for over 20 years providing gas calibration solutions to the gas analyzer industry and working with customers all over the world. Now as Vice President, Ms. Vrazel uses her business experience and technical expertise to guide business operations.

Danet M. Vrazel worked in the Chemical Industry with companies such as Hoechst Celanese and Solutia and did research in the Chemical Pathology Department at UTMB Galveston before working with KIN-TEK in 2001. As a Technical Sales/Service Representative for KIN-TEK, Ms. Vrazel learned techniques for calibrating gas analytical devices using permeation tubes and gas standard generators. Ms. Vrazel has been with KIN-TEK for over 20 years providing gas calibration solutions to the gas analyzer industry and working with customers all over the world. Now as Vice President, Ms. Vrazel uses her business experience and technical expertise to guide business operations.